Masterbatch lines

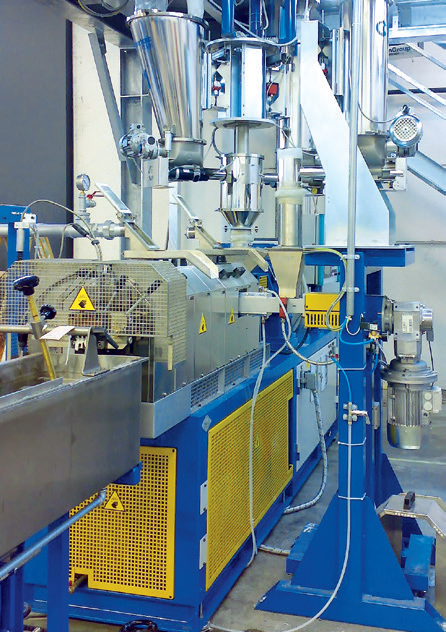

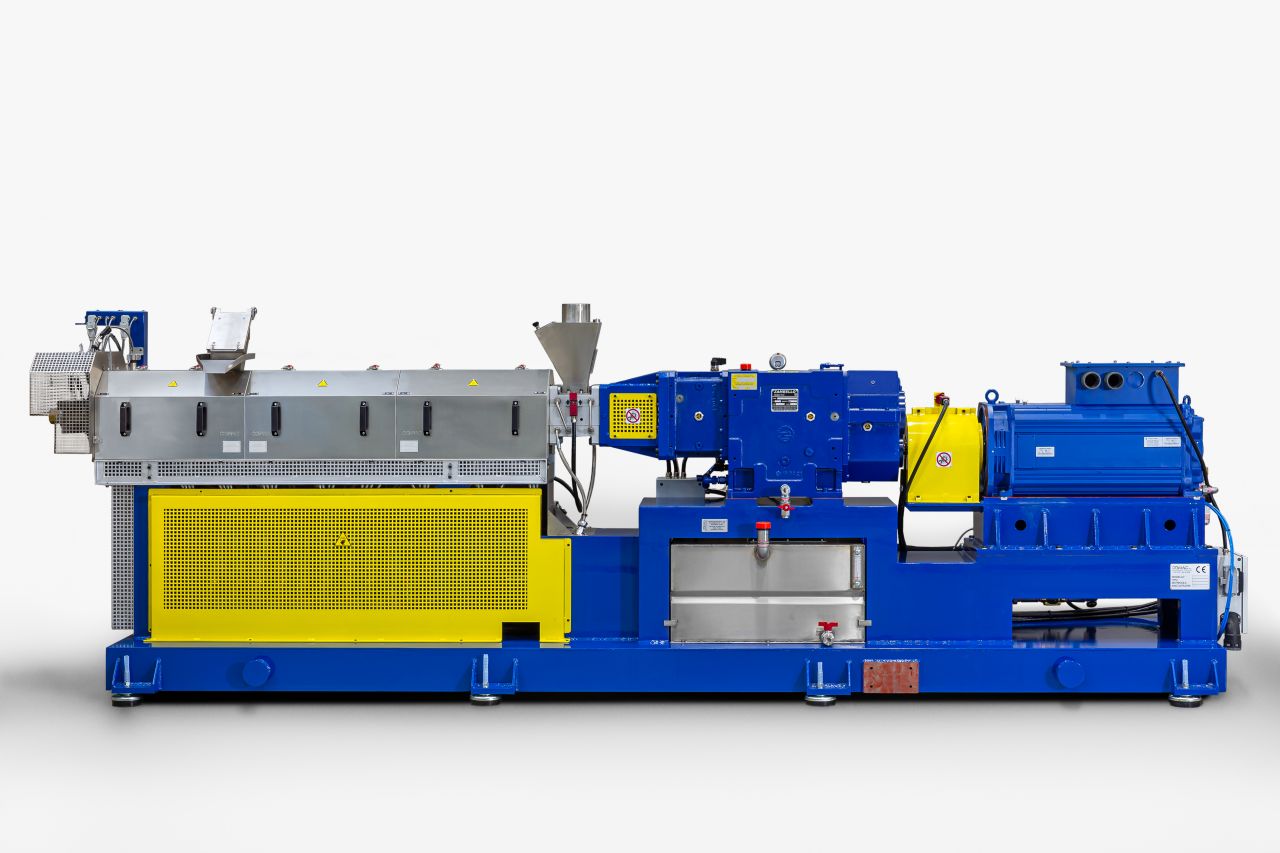

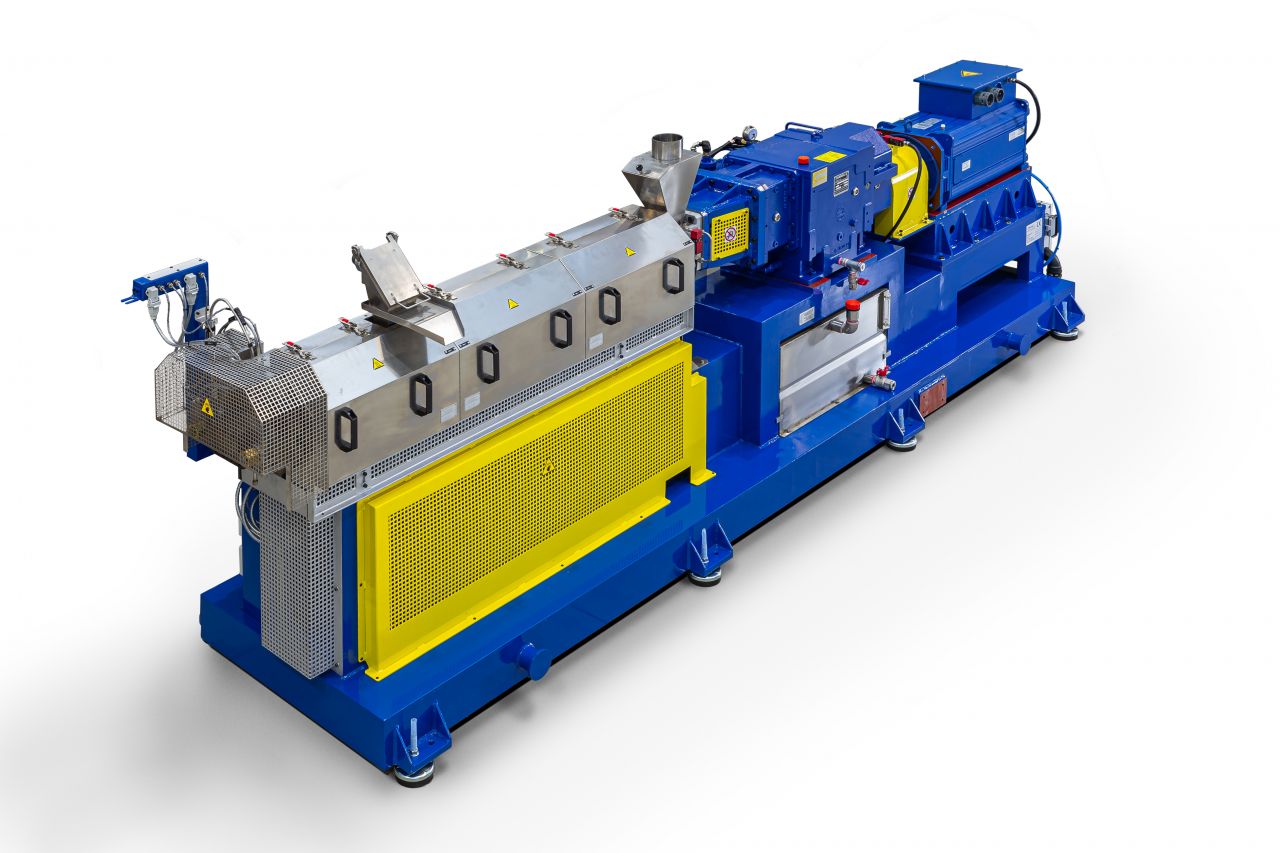

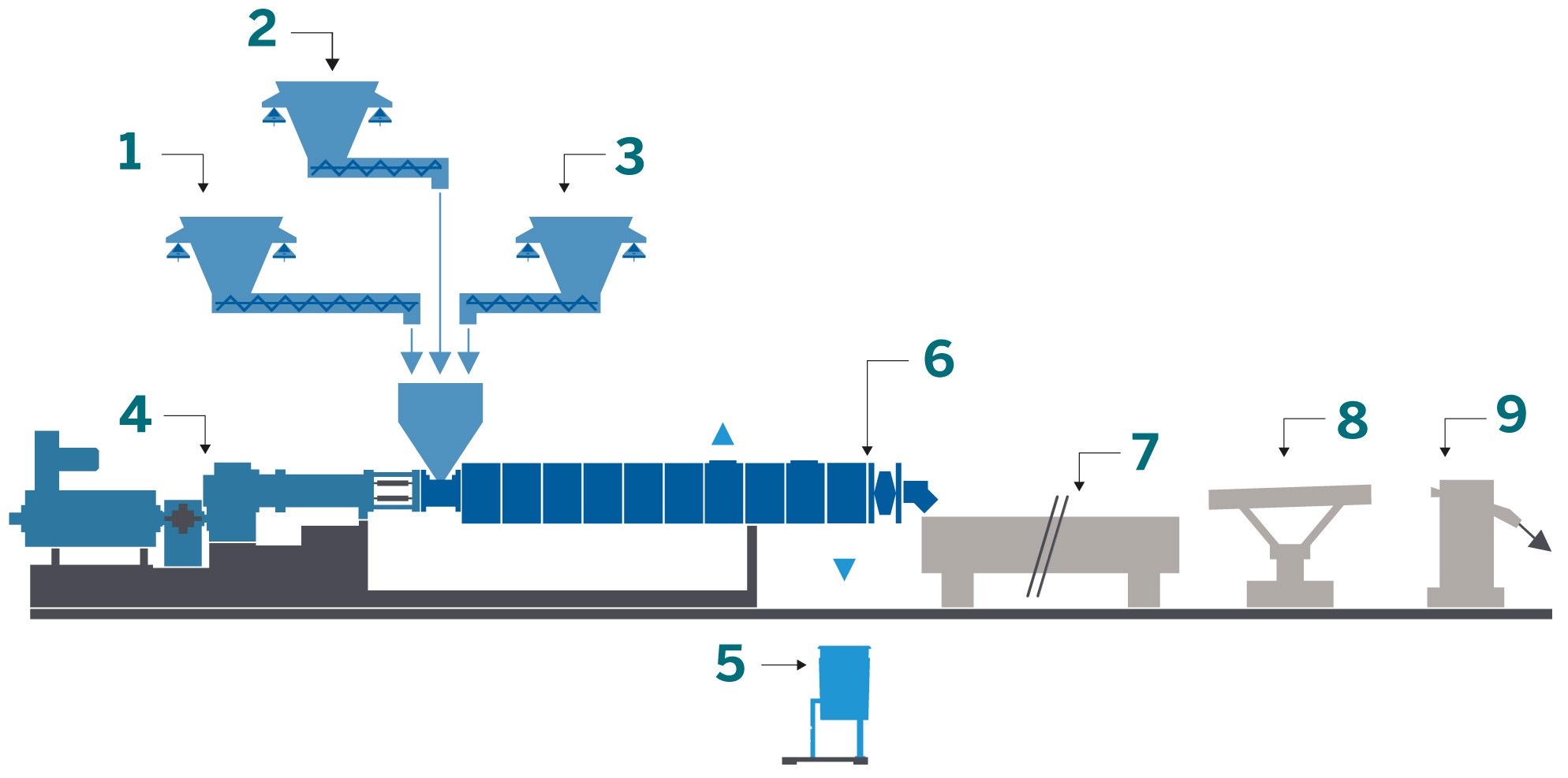

Optimized for the strict quality requirements of masterbatch producers, these lines are fitted with the most advanced solutions coming from 40 years of real experience in this field.

A high shear-rate and an extremely performing screw geometry enable to achieve high pigment concentrations in different polymer carriers with optimal dispersions.

A compenetration ratio of the screws up to ≅ 1.65 conjugates excellent quality with excellent production capacity.

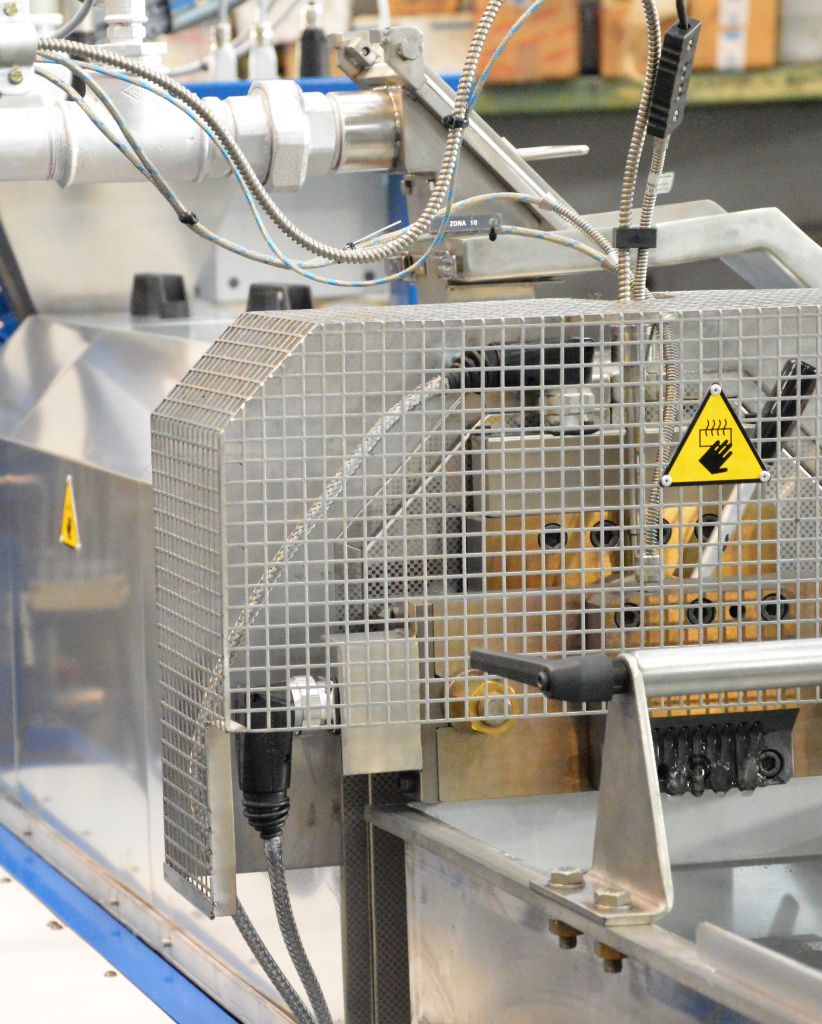

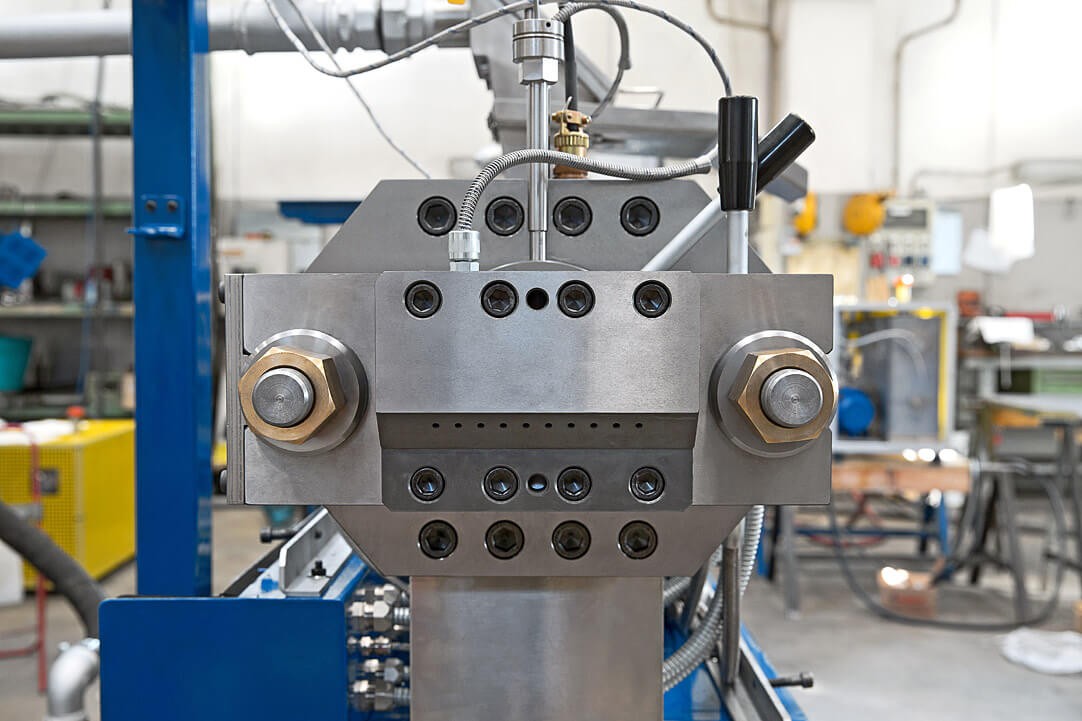

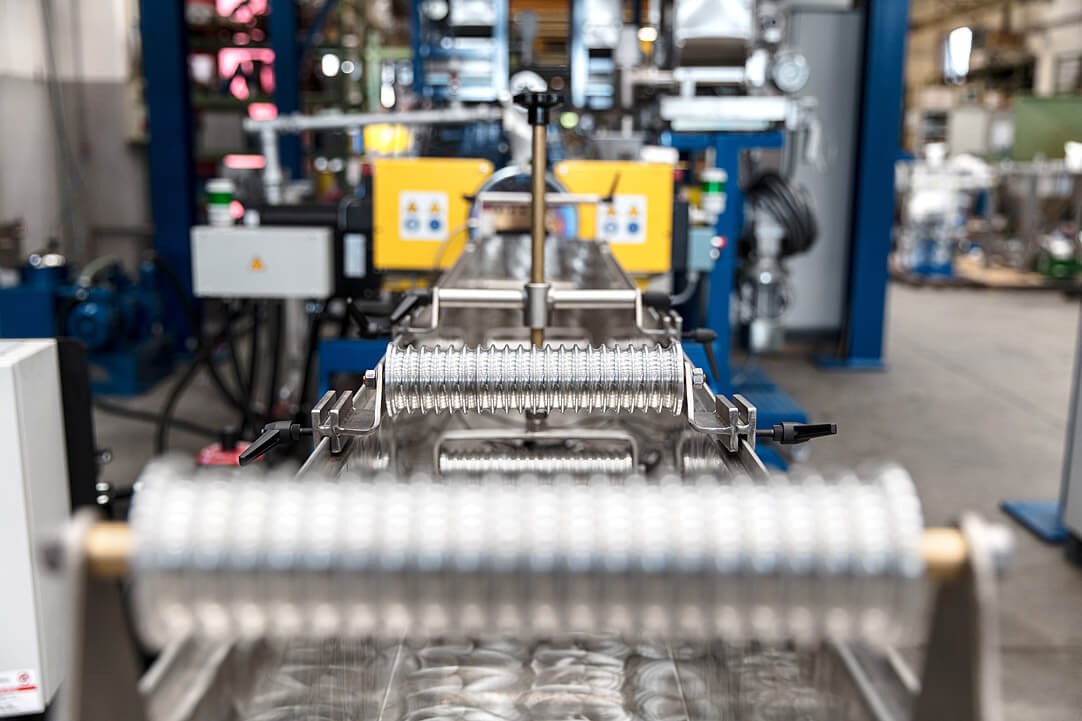

Self-cleaning screw profiles avoid prolonged production stops. Strand extrusion die heads are typically used on color/additive masterbatch and on compounding lines for some applications (e.g. glass fiber compounds). Screen changer and extrusion head are designed for quick opening and fast colour change. A control panel and automatic devices allow operators to manage production with minimum effort.

- dosage

- cooling tank

- drying tunnel

- pelletizer

| COMAC'S EXTRUDERS "EBC" - STANDARD/HIGH VOLUME | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| MODEL | EBC 40 | EBC 50 | EBC 60 | EBC 70 | EBC 90 | EBC108 | EBC 120 | EBC 135 | |

| Nominal diameter (mm) / High volume ( mm ) | 42/43 | 53/55 | 62/64 | 70/72 | 92/94 | 108/112 | 120/123 | 132/135 | |

| Screw number of lobes | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Screw center-to-center (mm) | 35 | 44,6 | 52 | 58 | 76 | 90 | 100 | 110 | |

| Screw speed (rpm) other values on request | 600 - 1200 | 600 - 1200 | 600 - 1200 | 300 - 1200 | 150 - 900 | 150 - 900 | 150 - 600 | 150 - 600 | |

| Torque on each screw (Nm) | HT (High Torque) | 472 | 976 | 1547 | 2146 | 4829 | 8020 | 11000 | 14600 |

| XT (Extra Torque) | 643 | 1331 | 2109 | 2927 | 6585 | 11000 | 15000 | 19900 | |

| L/D ratio (std. range) | 24 - 52 | 24 - 52 | 24 - 52 | 24 - 52 | 24 - 52 | 24 - 52 | 24 - 52 | 24 - 52 | |

| Indicative output (kg/h) | 100 - 250 | 200 - 500 | 300 - 750 | 500 - 1400 | 1000 - 2200 | 1100 - 3000 | 1200 - 4000 | 1700 - 6000 | |

| NOTE: L/D - typically, barrels are built-up by independently thermoregulated modules having 4-diameter length each; Output -the ranges here above want to give an idea on limits considering a variety of cases, but, figures can only be very indicative; actually achievable values strongly depend on raw material formulations, target products and relevant desired characteristics, as well as speed and process conditions. |

|||||||||