ENGINEERING & PRODUCTION

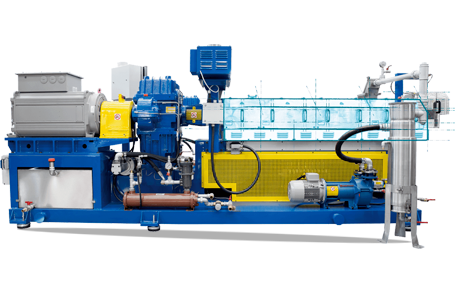

Every new COMAC project is also a step forward in our research programs. We perform rheological simulations with sophisticated software in combination with production tests and, thanks to a consolidated know-how, continuous updating and collaborations with highly renowned research centers, we constantly improve our products also in terms of process quality monitoring systems .

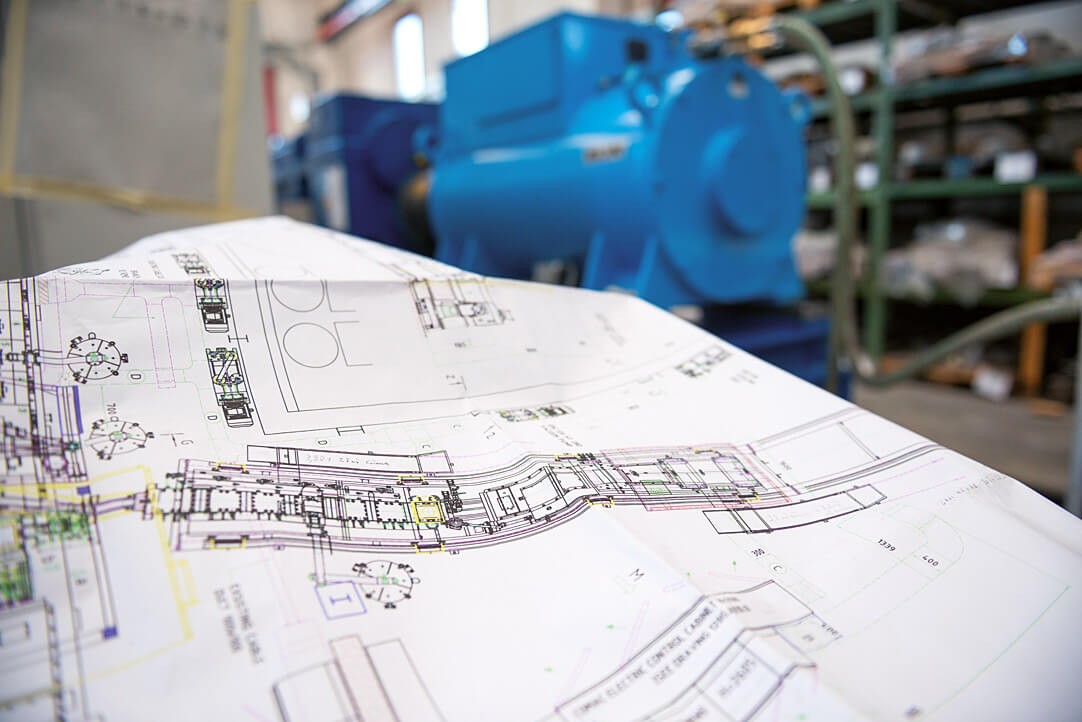

Each extruder is carefully designed to meet the specific needs of our customers; the whole process makes use of updated CAD / CAM technologies and is supported by the precious experience of our technical staff and qualified production personnel.

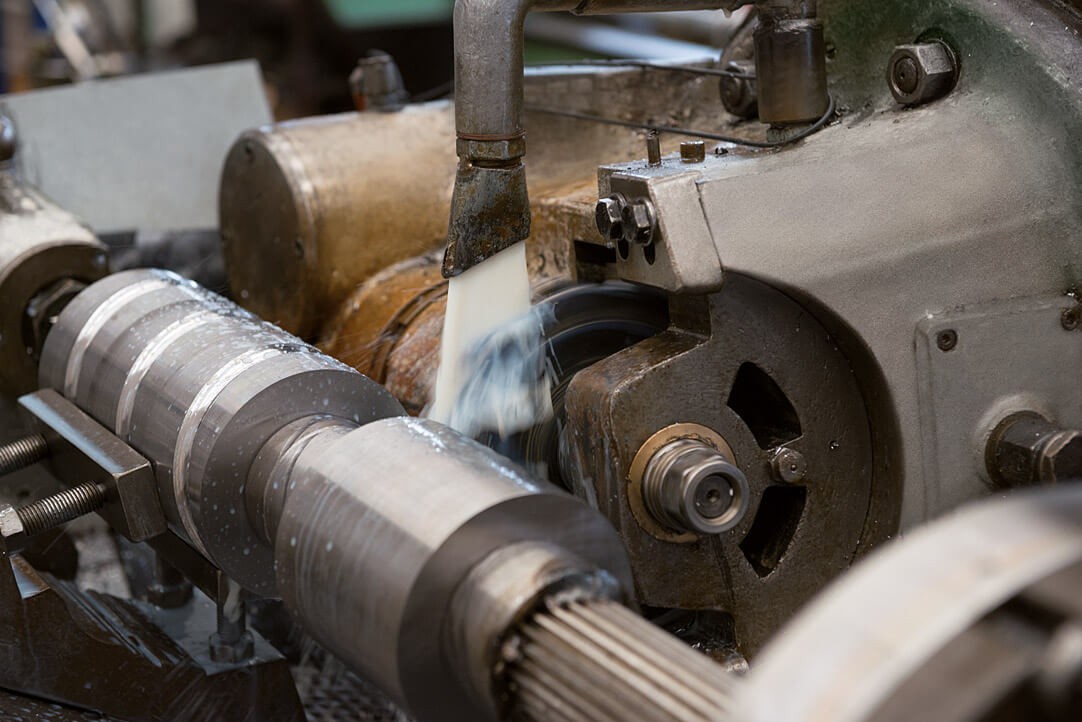

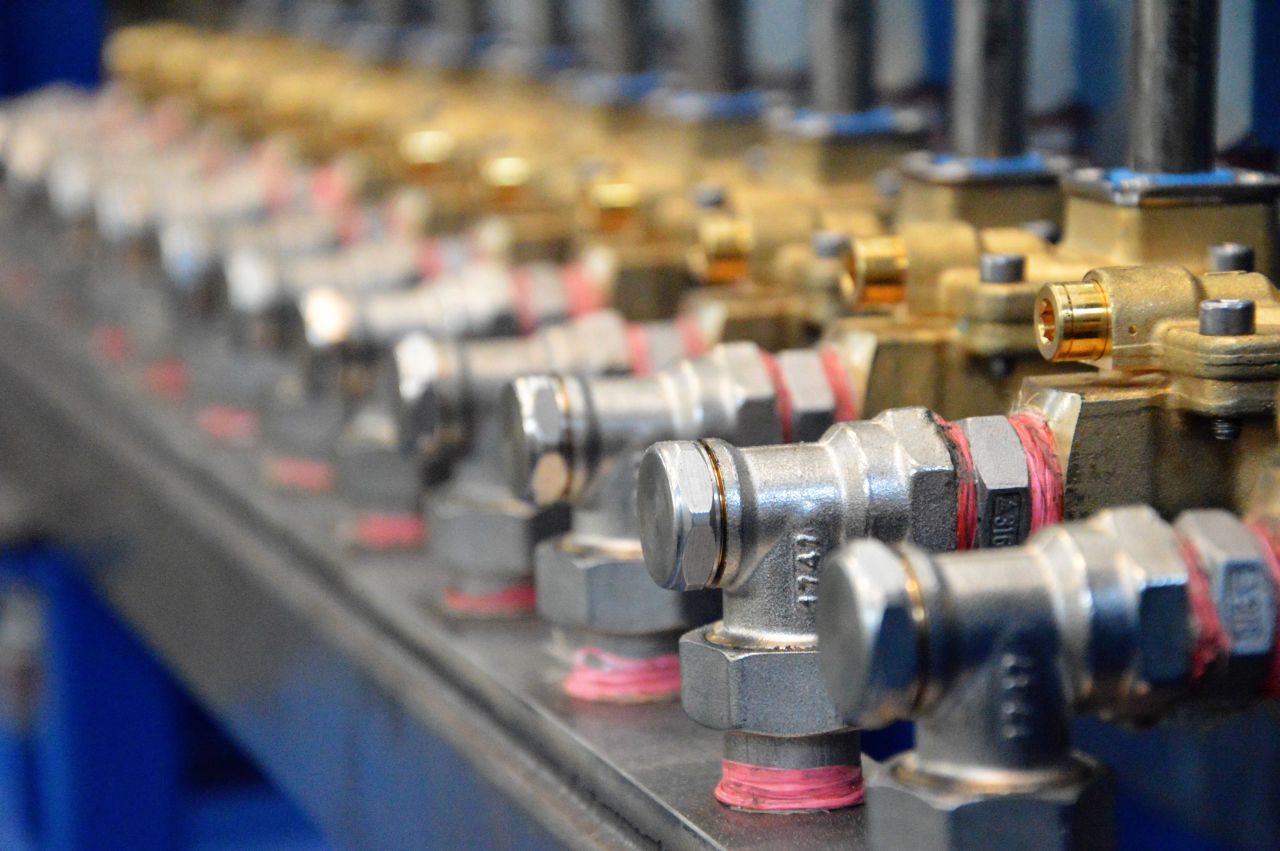

COMAC develops and directly manufactures all the main parts of its extruders giving form to the know-how gained over the years, thanks to the direct contact of production plant with the technical area.

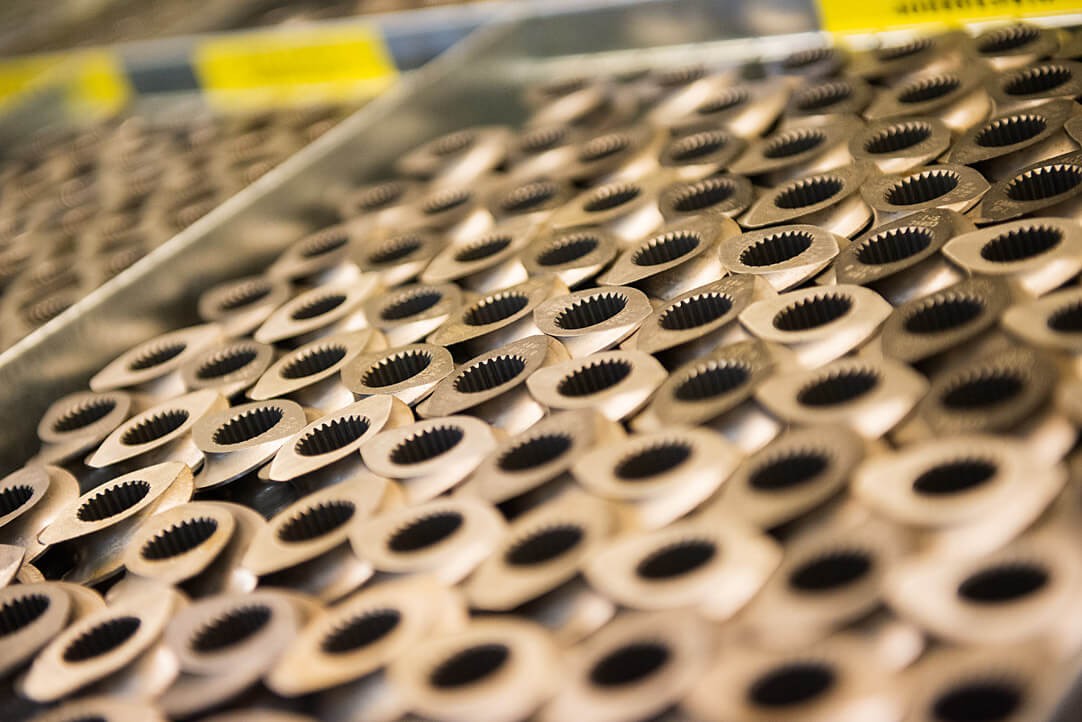

The accessory parts are supplied only by qualified suppliers of international caliber.

COMAC satisfies every customer need proposing the following services:

Our specialized staff is available for all your project and process needs.

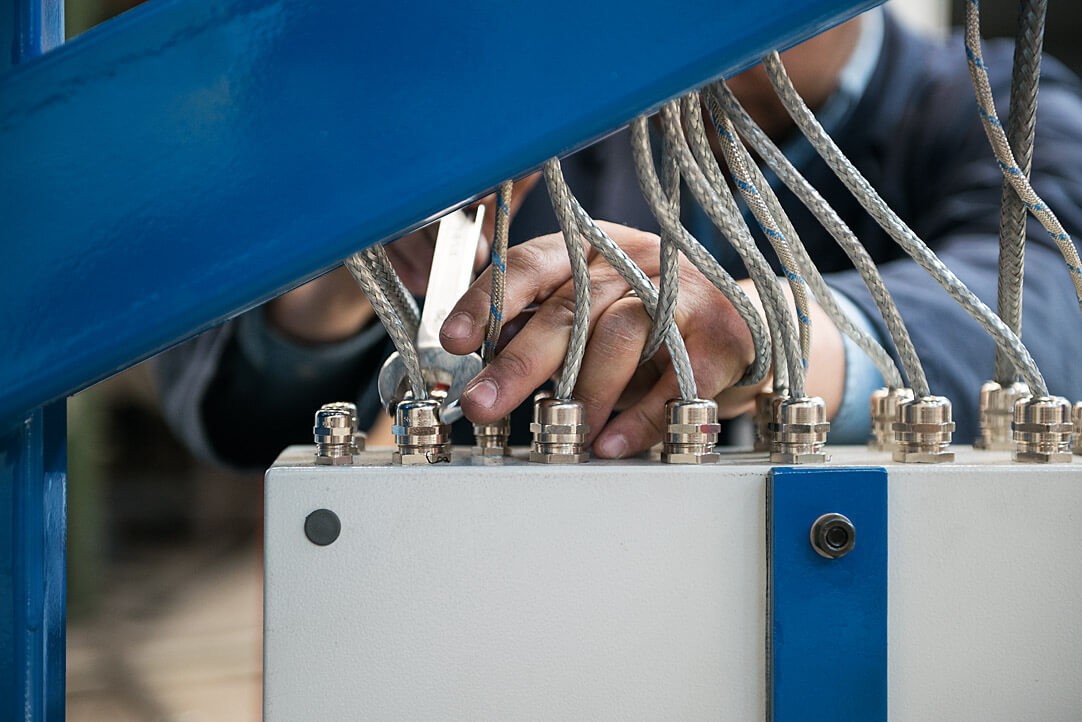

Our technicians accompany the customer up to the first system start-up of, also providing all the necessary instructions to be able to maneuver and manage the instruments / machines in complete autonomy.

(all our systems are equipped with "remote control" connection):

Possibility to intervene at any time with online support in real time; continuous monitoring of the extruder's performance and operating conditions.

All the key components are available on stock to allow our customers to avoid long maintenance stops.

Chance to modify the plant layout to meet any new production or process requirements.